Composition and structure

The lifting capacity is generally 0.3-80 tons, and the lifting height is 3-30 meters. It is composed of motor, transmission mechanism and drum or chain wheel, which can be divided into wire rope electric hoist and chain electric hoist. Among them, electric chain hoist is divided into imported and domestic two kinds; wire rope electric hoist is divided into single speed lifting and double speed lifting; micro electric hoist, winch and multi-function hoist.

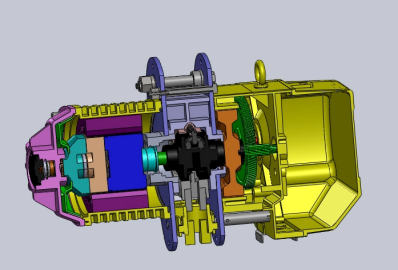

Reducer, lifting motor, running motor, flame breaker, cable sliding line, drum device, hook device, coupling, flexible cable current inductor, etc. are integrated with power and braking force.

Lifting capacity: 0.25t-80t

Lifting height: 3m-30m

Working level: m3, M4

Operating speed: 20 (30) m / min

Lifting speed: 8m / min

Installation and use

Electric hoist is generally installed on single beam crane, bridge crane, gantry crane and suspension crane. After a little modification, it can also be used as hoist. Therefore, it is a necessary machine to improve labor efficiency and working conditions.

Operating conditions

Ambient temperature: - 20 ℃~ + 40 ℃

Working system: intermediate jc25%

Heavy grade: jc40%

When the lifting capacity of the electric hoist in the intermediate working system is reduced by 30%, the electric hoist in the heavy working system is 40%.

More than 40% of heavy duty electric hoists are used in the case of heavy work, load often in the rated value or high safety factor.

Electric hoist structure reducer: it adopts three-stage fixed axis helical gear rotation mechanism, the gear and gear shaft are made of heat-treated alloy steel, and the box body and cover are made of high-quality cast iron, with tight assembly and good sealing. The reducer is a part of its own, which is very convenient for loading and unloading.

Control box: it can cut off the main circuit in case of emergency, and it is equipped with up and down stroke protection device. Ensure the safe operation of electric hoist. Electrical components have long service life and reliable use.

Steel wire rope: the hoisting steel wire rope includes phosphating coating steel wire rope, galvanized steel wire rope and stainless steel wire rope. The current national standard GB / t5972-1986 "code of practice for inspection and scrapping of steel wire rope for crane machinery" is implemented to ensure its durability.

Conical motor: the hoisting motor adopts large starting torque conical rotor braking asynchronous motor, without additional brake. The load duration rate of the motor is 25%, the motor adopts class B or class F insulation, and the motor protection grade is IP44 / IP54.

Button switch: it is easy to operate by hand. There are two ways: rope control and wireless remote control.

The components of electric hoist are: motor, transmission mechanism, drum and sprocket.

Structural drawing of electric hoist

According to the different positions of motor and drum, they can be roughly divided into four types

(1) The electric hoist whose axis of motor is perpendicular to the axis of drum adopts worm gear transmission device, which is large in width, heavy in structure, low in mechanical efficiency and difficult in processing. No manufacturer has produced this type of product.

(2) The electric hoist whose motor axis is parallel to the drum axis has the advantage of small height and length. Its disadvantages are large width, grouping, complex manufacturing and assembly, and large turning radius.

(3) The electric hoist with the motor installed in the drum has the advantages of small length and compact structure. Its main disadvantages are poor heat dissipation condition of motor, poor grouping, inconvenient inspection, installation and maintenance of motor, and complex power supply device.

(4) The electric hoist with the motor installed outside the drum has the advantages of good grouping, high degree of generalization, easy to change the lifting height and convenient installation and maintenance. Its disadvantage is that the length is large.

main features

The structure and characteristics of wire rope electric hoist: the machine adopts Mechatronics design, which can press different specifications of wire rope by changing different molds. It is simple and safe to control, and convenient to check, install and maintain the motor. Its main disadvantages are poor heat dissipation premise, poor grouping, and complex power supply device, manufacturing and assembly.

Classification and description of wire rope electric hoist the components of wire rope electric hoist are: motor, conveyor, drum and sprocket. According to the different positions of motor and drum, it can be roughly divided into four types. The pressed steel wire rope has the advantages of large tension, beautiful appearance and fast speed. It only takes a few minutes to crimp a set of steel wire rope, which greatly reduces the labor intensity and improves the work efficiency.

The electric hoist with the motor installed outside the drum has the advantages of good grouping, high degree of generalization, easy to change the lifting height and convenient device inspection.

Electric hoist is widely used, but there are few professionals who can operate electric hoist correctly. It is suggested that we should know more about electric hoist and make better use of all kinds of electric hoist in various fields.

Main categories

Electric hoists are mainly divided into: chain electric hoists, wire rope electric hoists (explosion-proof hoists), anti-corrosion electric hoists, double drum electric hoists, hoists, micro electric hoists, group crane electric hoists and multi-function hoists.

application area

Application fields: lifting, pulling, loading and unloading heavy objects, oil tank upside down welding, such as the installation and movement of various large and medium-sized concrete, steel structure and mechanical equipment, suitable for construction and installation companies, factories and mines of civil engineering and bridge construction, electric power, ship, automobile manufacturing, construction, highway, bridge, metallurgy, mining, slope tunnel, shaft treatment and protection and other infrastructure projects mechanical equipment.

matters needing attention

(1) Inspection before use

a. There should be no obstacles and floating objects in the walking range of the operator, the sight range and the route of heavy objects.

b. The up and down, left and right directions of the manual control button shall be accurate and sensitive, and the motor and reducer shall have no abnormal sound.

c. The brake should be sensitive and reliable.

d. There shall be no foreign matter on the running track of electric hoist.

e. The action of upper and lower limit positioner should be accurate and sensitive.

f. The hook stop nut shall be firmly fastened.

g. The hook shall rotate flexibly in horizontal and vertical directions.

h. The hook pulley shall rotate flexibly.

i. There shall be no obvious crack on the wire rope, which shall be arranged in order on the drum, and there shall be no signs of breaking off the pulley groove, twisting, folding, etc., with good lubrication.

j. The lifting aids are normal.

k. The working environment temperature of electric hoist is - 25 ~ + 40 ℃

l. Electric hoist is not suitable for places full of corrosive gas or relative humidity greater than 85%. It can not replace explosion-proof hoist. It is not suitable for lifting molten metal or toxic, flammable and explosive materials.

(2) It is not allowed to lift or unload heavy objects on the side of the electric hoist, and it is forbidden to use the electric hoist with overload.

(3) In the process of use, the operator should check whether the wire rope is disorderly buckled, knotted, grooved, worn and other phenomena at any time. If any, it should be eliminated in time, and the safety and reliability of the rope guide and limit switch should be checked frequently.

(4) In daily work, it is not allowed to use the limiter artificially to stop the lifting of heavy objects or stop the operation of the equipment.

(5) After the work, turn off the main power switch and cut off the main power.

(6) Special maintenance personnel shall be set up to check the main performance and safety status of the electric hoist once a week, and remove the fault in time.

Contact: Rainie

Phone: 86-15268385214

Tel: 86-15268385214

Email: Rainie@yingerhoist.com

Add: No4750 Dongfeng West Street,Weicheng District,Weifang,Shandong China